Tarp roll manufacturing factories in Vietnam have emerged as a cornerstone of the global market, driven by the escalating demand for durable, versatile, and high-quality covering solutions. By integrating cutting-edge technology, adhering to stringent international standards, and offering competitive pricing, these factories have established themselves as trusted partners for importers across the USA, Europe, Japan, and beyond. This article delves into the key factors that position Vietnam’s tarp roll manufacturing factories as a top choice for global buyers and highlights their pivotal role in addressing the world’s covering needs.

1. International Quality Standards From Tarp Roll Manufacturing Factories

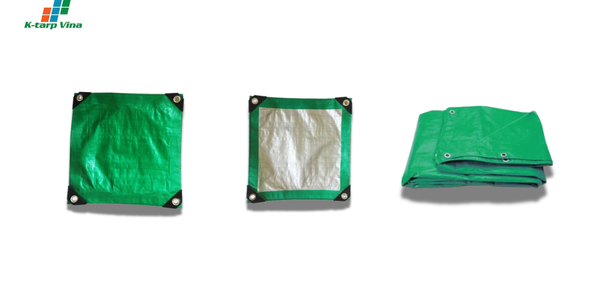

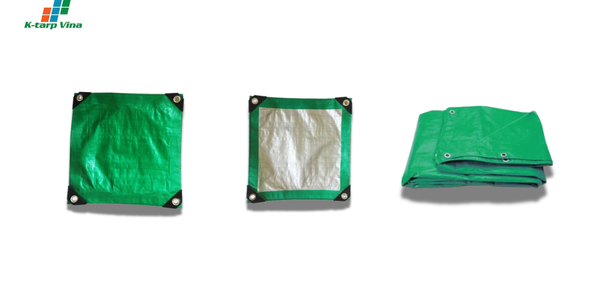

Vietnam’s tarp roll manufacturing factories, such as K-Tarp Vina, have made substantial investments in state-of-the-art technology and rigorous production processes to ensure their products meet global benchmarks, including ISO 9001 certification and the demanding requirements of markets like the USA, European Union, and Japan. Several critical factors contribute to their ability to compete on the international stage:

High-Quality Raw Materials

The use of premium-grade polyethylene (PE) is a hallmark of Vietnam’s tarp rolls. This material provides exceptional mechanical strength, ensuring resistance to tearing, puncturing, and abrasion. The high-quality PE used in these factories is sourced from reliable suppliers, often meeting international material safety and performance standards, which enhances the durability and reliability of the final product.

Advanced Coating Technologies

To cater to diverse environmental conditions, tarp rolls are treated with specialized coatings that offer UV resistance, waterproofing, and, in some cases, fire-retardant properties. These coatings ensure that the tarps can withstand prolonged exposure to sunlight, heavy rainfall, and extreme temperatures without degrading. For instance, fire-retardant tarps meet stringent safety regulations, such as those required in the USA and EU, making them suitable for high-risk applications like construction and industrial use.

Rigorous Quality Control

Every tarp roll undergoes meticulous quality control checks before leaving the factory. These checks include testing for thickness consistency, tensile strength, tear resistance, and coating integrity. Advanced testing equipment ensures that no defective products reach the market, giving buyers confidence in the reliability of Vietnamese tarp rolls. This commitment to quality has enabled these factories to penetrate demanding markets, where precision and consistency are non-negotiable.

As a result, tarp rolls from Vietnam not only serve domestic industries but are also exported to some of the world’s most quality-conscious markets. They are widely used in applications ranging from construction and agriculture to transportation, providing dependable performance in diverse conditions.

Learn more: Alibaba Ktarp Vina

2. Cutting Edge Manufacturing Technology

Vietnam’s tarp roll manufacturing factories leverage advanced technology, often acquired through partnerships or technology transfers from leading industrial nations like South Korea, Japan, and Germany. This technological edge allows them to produce high-quality tarp rolls efficiently and at scale. Key technological advancements include:

Modern Leno Weaving Machines

These factories employ state-of-the-art leno weaving machines, which create a unique cross-woven structure that enhances the tarp’s strength and tear resistance. This weaving technique ensures that even if a tear occurs, it does not propagate easily, making the tarps ideal for heavy-duty applications such as covering construction sites or protecting agricultural produce.

UV and Waterproof Coating Systems

Sophisticated coating systems apply UV-resistant and waterproof layers with precision, ensuring uniform coverage across the entire tarp surface. These coatings are designed to protect the tarps from degradation caused by prolonged sun exposure or moisture, making them suitable for use in harsh climates, from tropical regions to cold, wet environments in Europe.

Automated Production Lines

Automation plays a significant role in Vietnam’s tarp roll manufacturing. Automated cutting, folding, and packaging processes minimize human error, improve product consistency, and accelerate production timelines. Factories in industrial hubs like Phu Tho, Bac Ninh, and Binh Duong are equipped with fully automated production lines capable of producing large-format tarp rolls to meet bulk orders from international clients. This automation also reduces production costs, enabling factories to offer competitive pricing without compromising quality.

F

The versatility of tarp rolls produced by Vietnam’s manufacturing factories has made them indispensable across a wide range of industries worldwide. Their ability to meet diverse application needs has solidified Vietnam’s position as a global leader in tarp production. Key applications include:

Construction

In the construction industry, tarp rolls are used to cover scaffolding, protect building materials from weather damage, and create temporary roofing for large-scale projects. In markets like the USA and Europe, where construction standards are stringent, Vietnamese tarp rolls are valued for their durability and weather resistance, ensuring project timelines are met without delays caused by environmental factors.

Agriculture

In agricultural markets like Japan and South Korea, where precision and quality are paramount, tarp rolls are used to create greenhouses, cover soil to retain moisture, and protect crops from adverse weather. The UV-resistant and waterproof properties of these tarps ensure optimal growing conditions, while their durability reduces the need for frequent replacements, saving costs for farmers.

Transportation and Logistics

Tarp rolls play a critical role in protecting goods during transportation, whether on trucks, ships, or containers. Their ability to shield cargo from rain, dust, and UV exposure makes them essential for international shipping routes. Vietnamese tarp rolls are particularly popular in logistics-heavy markets like Singapore and the Middle East, where reliable covering solutions are in high demand.

Outdoor Events

From music festivals in Australia to trade fairs in Canada, tarp rolls are used to create temporary shelters, stage coverings, and exhibition booths. Their customizable sizes, colors, and features (such as mold resistance) make them ideal for outdoor events, where aesthetics and functionality are equally important.

The ability to tailor tarp rolls to specific requirements—such as custom dimensions, specialized coatings, or branding—has made Vietnam’s products highly sought after by global clients with unique needs.

4. Competitive Pricing: A Strategic Advantage

Vietnam’s tarp roll manufacturing factories have gained a competitive edge in the global market due to their ability to offer high-quality products at lower costs than competitors in China, South Korea, or Europe. Several factors contribute to this cost advantage:

Skilled and Cost-Effective Workforce

Vietnam boasts a large, skilled labor force with expertise in manufacturing, available at a fraction of the cost of labor in developed countries. This allows factories to maintain high production standards while keeping operational costs low.

Accessible Raw Materials

The availability of high-quality polyethylene at competitive prices, often sourced locally or from regional suppliers, reduces material costs. Additionally, Vietnam’s well-developed supply chain ensures a steady flow of raw materials, minimizing production delays.

businesses seeking value without compromising performance.

5. Commitment To Environmental Sustainability

As environmental concerns take center stage in global markets, Vietnam’s tarp roll manufacturing factories are aligning with sustainability trends to meet the expectations of eco-conscious buyers. Key initiatives include:

1. International Quality Standards From Tarp Roll Manufacturing Factories

Vietnam’s tarp roll manufacturing factories, such as K-Tarp Vina, have made substantial investments in state-of-the-art technology and rigorous production processes to ensure their products meet global benchmarks, including ISO 9001 certification and the demanding requirements of markets like the USA, European Union, and Japan. Several critical factors contribute to their ability to compete on the international stage:

High-Quality Raw Materials

The use of premium-grade polyethylene (PE) is a hallmark of Vietnam’s tarp rolls. This material provides exceptional mechanical strength, ensuring resistance to tearing, puncturing, and abrasion. The high-quality PE used in these factories is sourced from reliable suppliers, often meeting international material safety and performance standards, which enhances the durability and reliability of the final product.

Advanced Coating Technologies

To cater to diverse environmental conditions, tarp rolls are treated with specialized coatings that offer UV resistance, waterproofing, and, in some cases, fire-retardant properties. These coatings ensure that the tarps can withstand prolonged exposure to sunlight, heavy rainfall, and extreme temperatures without degrading. For instance, fire-retardant tarps meet stringent safety regulations, such as those required in the USA and EU, making them suitable for high-risk applications like construction and industrial use.

Rigorous Quality Control

Every tarp roll undergoes meticulous quality control checks before leaving the factory. These checks include testing for thickness consistency, tensile strength, tear resistance, and coating integrity. Advanced testing equipment ensures that no defective products reach the market, giving buyers confidence in the reliability of Vietnamese tarp rolls. This commitment to quality has enabled these factories to penetrate demanding markets, where precision and consistency are non-negotiable.

As a result, tarp rolls from Vietnam not only serve domestic industries but are also exported to some of the world’s most quality-conscious markets. They are widely used in applications ranging from construction and agriculture to transportation, providing dependable performance in diverse conditions.

Learn more: Alibaba Ktarp Vina

2. Cutting Edge Manufacturing Technology

Vietnam’s tarp roll manufacturing factories leverage advanced technology, often acquired through partnerships or technology transfers from leading industrial nations like South Korea, Japan, and Germany. This technological edge allows them to produce high-quality tarp rolls efficiently and at scale. Key technological advancements include:

Modern Leno Weaving Machines

These factories employ state-of-the-art leno weaving machines, which create a unique cross-woven structure that enhances the tarp’s strength and tear resistance. This weaving technique ensures that even if a tear occurs, it does not propagate easily, making the tarps ideal for heavy-duty applications such as covering construction sites or protecting agricultural produce.

UV and Waterproof Coating Systems

Sophisticated coating systems apply UV-resistant and waterproof layers with precision, ensuring uniform coverage across the entire tarp surface. These coatings are designed to protect the tarps from degradation caused by prolonged sun exposure or moisture, making them suitable for use in harsh climates, from tropical regions to cold, wet environments in Europe.

Automated Production Lines

Automation plays a significant role in Vietnam’s tarp roll manufacturing. Automated cutting, folding, and packaging processes minimize human error, improve product consistency, and accelerate production timelines. Factories in industrial hubs like Phu Tho, Bac Ninh, and Binh Duong are equipped with fully automated production lines capable of producing large-format tarp rolls to meet bulk orders from international clients. This automation also reduces production costs, enabling factories to offer competitive pricing without compromising quality.

F

The versatility of tarp rolls produced by Vietnam’s manufacturing factories has made them indispensable across a wide range of industries worldwide. Their ability to meet diverse application needs has solidified Vietnam’s position as a global leader in tarp production. Key applications include:

Construction

In the construction industry, tarp rolls are used to cover scaffolding, protect building materials from weather damage, and create temporary roofing for large-scale projects. In markets like the USA and Europe, where construction standards are stringent, Vietnamese tarp rolls are valued for their durability and weather resistance, ensuring project timelines are met without delays caused by environmental factors.

Agriculture

In agricultural markets like Japan and South Korea, where precision and quality are paramount, tarp rolls are used to create greenhouses, cover soil to retain moisture, and protect crops from adverse weather. The UV-resistant and waterproof properties of these tarps ensure optimal growing conditions, while their durability reduces the need for frequent replacements, saving costs for farmers.

Transportation and Logistics

Tarp rolls play a critical role in protecting goods during transportation, whether on trucks, ships, or containers. Their ability to shield cargo from rain, dust, and UV exposure makes them essential for international shipping routes. Vietnamese tarp rolls are particularly popular in logistics-heavy markets like Singapore and the Middle East, where reliable covering solutions are in high demand.

Outdoor Events

From music festivals in Australia to trade fairs in Canada, tarp rolls are used to create temporary shelters, stage coverings, and exhibition booths. Their customizable sizes, colors, and features (such as mold resistance) make them ideal for outdoor events, where aesthetics and functionality are equally important.

The ability to tailor tarp rolls to specific requirements—such as custom dimensions, specialized coatings, or branding—has made Vietnam’s products highly sought after by global clients with unique needs.

4. Competitive Pricing: A Strategic Advantage

Vietnam’s tarp roll manufacturing factories have gained a competitive edge in the global market due to their ability to offer high-quality products at lower costs than competitors in China, South Korea, or Europe. Several factors contribute to this cost advantage:

Skilled and Cost-Effective Workforce

Vietnam boasts a large, skilled labor force with expertise in manufacturing, available at a fraction of the cost of labor in developed countries. This allows factories to maintain high production standards while keeping operational costs low.

Accessible Raw Materials

The availability of high-quality polyethylene at competitive prices, often sourced locally or from regional suppliers, reduces material costs. Additionally, Vietnam’s well-developed supply chain ensures a steady flow of raw materials, minimizing production delays.

businesses seeking value without compromising performance.

5. Commitment To Environmental Sustainability

As environmental concerns take center stage in global markets, Vietnam’s tarp roll manufacturing factories are aligning with sustainability trends to meet the expectations of eco-conscious buyers. Key initiatives include:

Vận hành bởi Trương Anh Vũ®

Vận hành bởi Trương Anh Vũ®